Accelerating PBFAM Development and Use Through Open Source Systems

An Open Architecture Framework Enables the Use of PBFAM for Development Opportunities and Custom Applications.

September 16, 2019

PROBLEM

High volume production of critical metal components via powder bed fusion additive manufacturing (PBFAM) must meet rigid engineering and quality standards that exceed current capabilities.

There are three key challenges in transitioning PBFAM from rapid prototyping to manufacturing: (1) machine robustness; (2) adaptation to custom applications; and (3) process monitoring and feedback.

Industry demand to address these challenges is outpacing machine suppliers’ and technology providers’ ability to provide capable, robust solutions—an issue that has evolved in part because of the closed architecture approach of existing OEMs.

OBJECTIVE

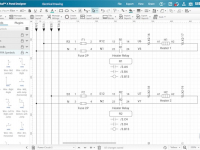

The objective of this project was to develop and demonstrate open architecture controls to foster thirdparty applications for PBFAM by establishing a design in which third-party developers would have ready access to standardized PBFAM control hardware.

Specifically the team sought to accelerate the development of subsystems for process optimization and control of the thermal environment; multi-modal operation, such as using multiple energy sources or incorporating subtractive technology; flexibly-sized powder beds; and in-process measurement and feedback control.

Fill out the information below to download the resource.

Latest News